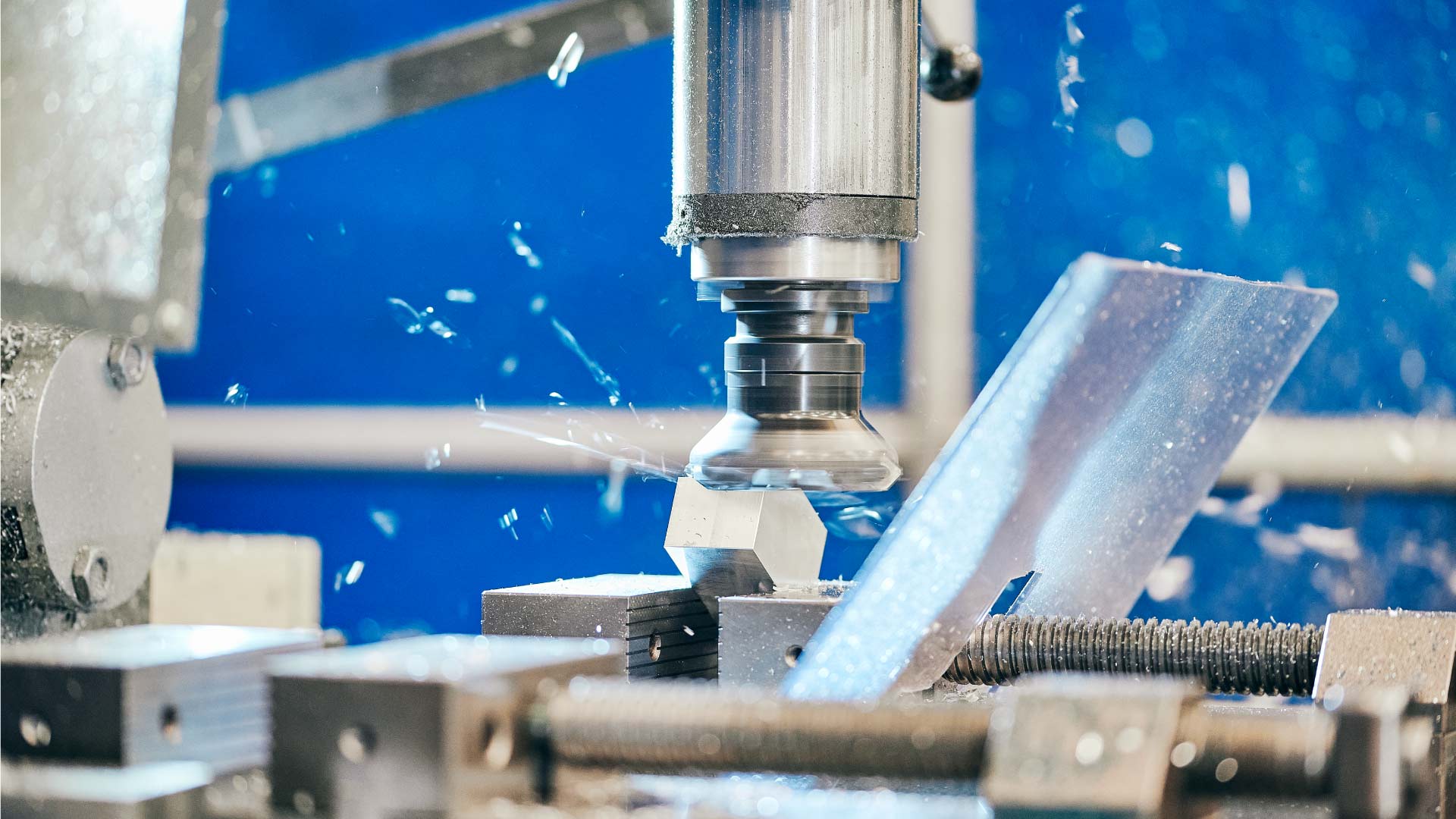

4.0 TECHNOLOGY

Quality and innovation

The professional training of our operators is complemented by the 4.0 technology of our machine park and the use of software that allows us to work with speed and precision, controlling every stage of the production process.

FOM AXEL 5 CNC 5 AXIS VERSION 7.5 METRES

useful working length 7.5 metres

18,000 rpm

20 tools + blade ø 500 mm

pneumatic clamps with independent positioning control

pendular machining on two areas with pneumatic stops

EMCO MAXMILL 500 CNC 5 ASSI

corsa 650 x 550 x 500 mm

10.000 giri /min

CNC Siemens Sinumerik 840d sl Shopmill

tavola 600×600 mm

rotazione asse b 100°

rotazione asse c 360°

30 utensili

sonda di misura Renishaw

HAAS VF3SS CNC 3 AXIS

stroke 1000 x 500 x 600 mm

12,000 rpm

table 1200 x 450 mm

30 tools

electronic touch probe

HAAS MINIMILL2 CNC 3 AXIS

stroke 500 x 400 x 350 mm

6,000 rpm

table 1000 x 350 mm

10 tools

EMCO EMCOTURN E65 CNC TWIN-SPINDLE LATHE

double spindle with workpiece spool

stroke 210 / ± 40 / 610 mm

bar passage ø 65 mm

CNC Siemens Sinumerik 828d Shopturn

max. turning ø 500 mm

distance between spindles 680 mm

max. spindle speed 5,000 rpm

12 motorised tools

OEMME SH400AR ASCENDING MITER SAW

blade ø 400 mm automatic rising

head rotation with mechanical stop

hydropneumatic blade feed with output speed control valve

Brown & Sharpe / DEA MANUAL MEASURING MACHINE

model b&s microval

striker table 400×600

tutor software for windows

Explore

Discover other sectors

Modular structures

We specialize in the production of a wide range of modular solutions for different industrial and civil applications.

Machine Guards

Tailor-made safety solutions designed to protect operators and mechanical components from the risks associated with machine handling.

Machining

Machining of small to medium-sized parts made to customer drawings, even in small batches, using state-of-the-art computerized numerical control machines.

FAQ

frequently asked questions

Quick clarifications and useful information

to get to know the entirety of our offer.

Aluminium profiles lend themselves to many applications including:

- Frames for machinery and automation lines

- Fixed and removable machine guards

- Linear sliding systems

- Perimeter protections

- Soundproof cabins

- Partition Panels

- Workstations

- Drawer cabinets and workshop furniture

- Metal shelving

Our structures are made from aluminium profiles that are selected and adapted according to project specifications. In order to provide a complete product, we have a precision machining department that allows us to produce complementary elements in stainless steel, aluminium and plastic in-house.

Our sales department is available to understand your needs and submit customised proposals based on your specifications.

You can contact us by writing to commerciale@tpf-srl.com

Our department is equipped with state-of-the-art machinery to perform milling, turning, grinding and galvanic treatments. We process stainless steel, aluminium and plastic in small and medium-sized batches. This department works both in support of the realisation of aluminium structures and independently to produce components according to customer drawings.