WHO WE ARE

Discover T.P.F. s.r.l.

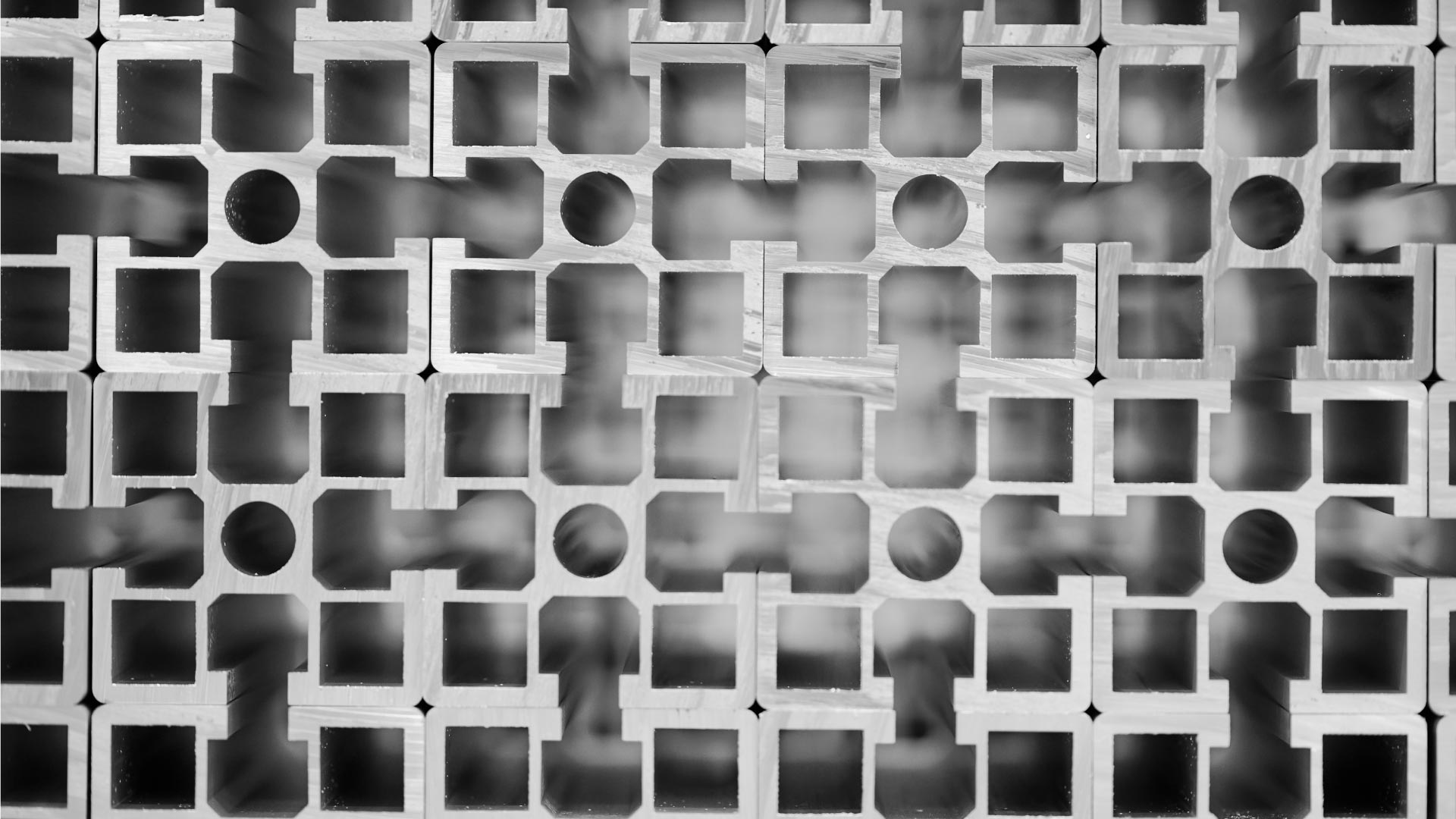

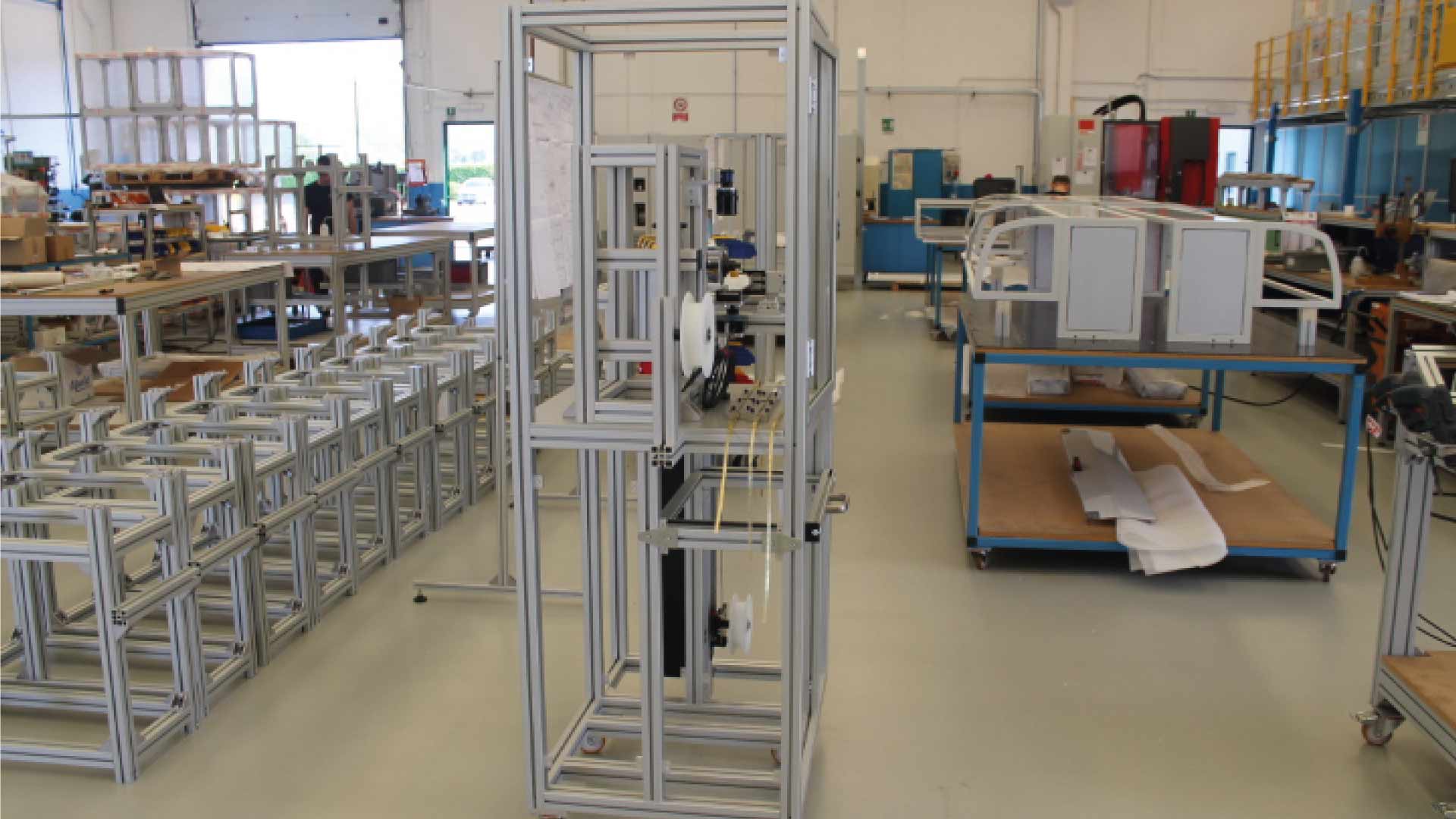

For more than twenty years in T.P.F. we work aluminum profiles to create customized modular structures and covers, giving shape to our customers’ projects.

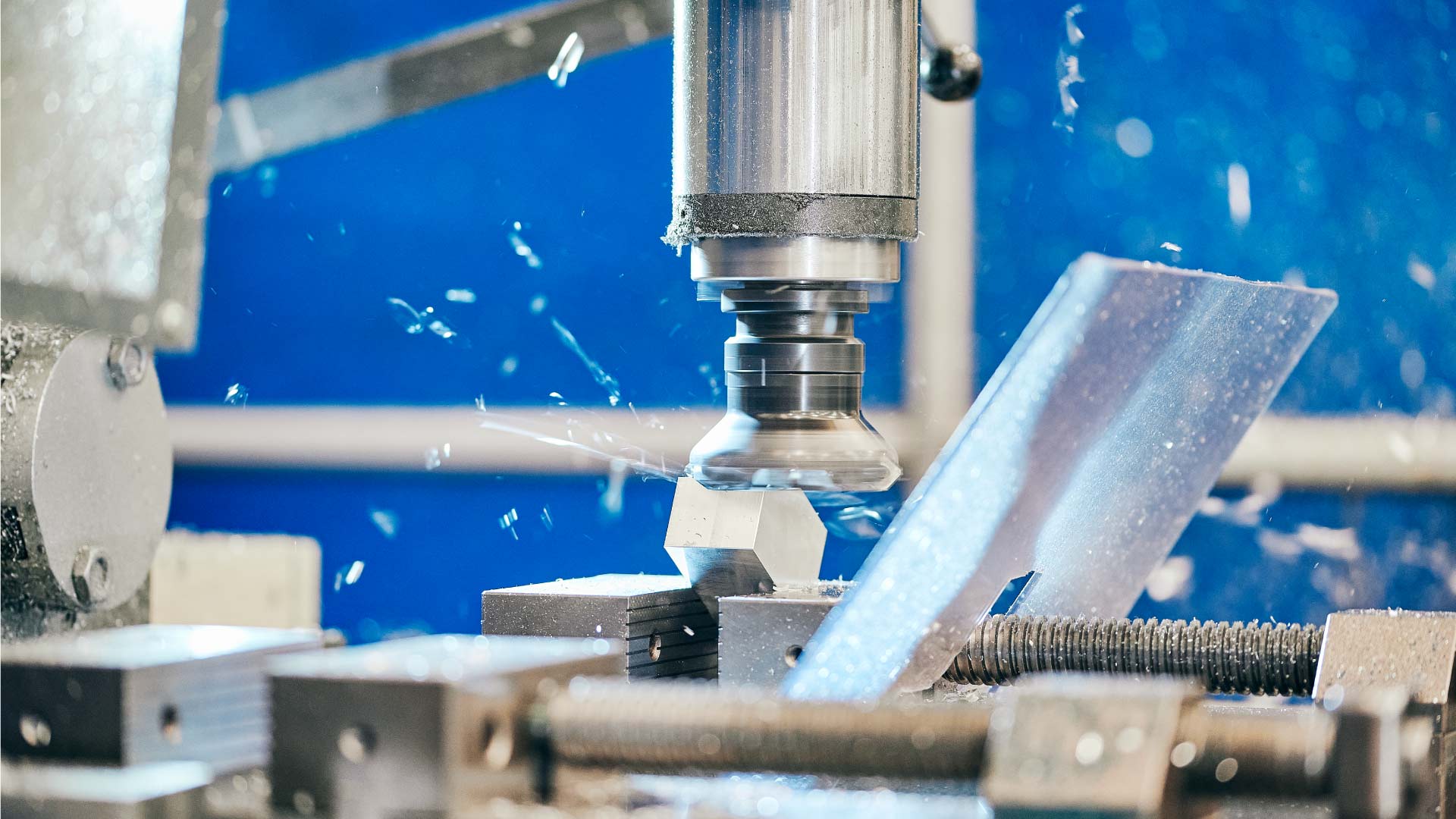

Our production is equipped with a mechanical processing department at the service of project specifications, capable of creating parts, based on customer designs, intended for industry.

HISTORY

At your side for more than 20 years

We were born in 1999 in the mechanical assembly sector. From the beginning we did not simply limit ourselves to the production of standard structures, but we actively committed ourselves to the creation of tailor-made solutions that specifically respond to the needs of our customers. This attention to customization, combined with more than twenty years of experience in the sector, testifies to our deep commitment to quality and innovation.

OUR VALUES

Passion, care and reliability.

Innovation

For us, the passion for our work combined with technological innovation in production is the key to the success

of our projects.

Attention to detail

Well-established production processes and control plans for the various production stages guarantee a final result that conforms to and meets the customer’s expectations.

Reliability

Attention to each individual project and tailor-made productions make us a partner capable of supporting our customers over time.

Security

We have always paid special attention to corporate welfare by paying the utmost attention to the safety and comfort of our

employees.

OUR EXPERIENCE

Why an aluminum profile structure?

The decision to focus our business on building modular structures using aluminium profiles stems from our awareness and in-depth knowledge of the advantages this material offers.

Advantages

Aluminium is a light and strong material that lends itself to various applications in industry, particularly for the construction of machinery frames and complementary structures.

Efficiency

A lean production process with minimal risk of failure, combined with lower transport costs due to the light weight of the material, make this a particularly efficient choice.

Sustainability

Aluminium profiles and components are 100 per cent recyclable without loss of properties. This offers an additional advantage by meeting the necessary requirements of environmental sustainability.

FAQ

frequently asked questions

Quick clarifications and useful information

to get to know the entirety of our offer.